Chemical CompositionAS2738.2 – 1984, Compositions & Designations | Copper | Lead | Zinc | | Min | 56.0 | 2.5 | – | | Max | 60.0 | 4.5 | Remainder |

Equivalent Alloy Specifications| Specification | Designation | | UNS | C38510 | | ISO | CuZn39Pb3 | | BSI | CZ121 |

Australian Product Specifications| Specification | Product Form | | AS1567 | Wrought Rods, Bars & Sections | | AS2738 | Compositions & Designations |

Fabrication Properties| Joining Technique | Suitability | Soft Soldering | Good | Silver Soldering | Fair – Good | Brazing | Good | Oxy Acetylene Welding | Fair | Gas Shielded Arc Welding | Not Recommended | Coated Metal Arc Welding | Not Recommended | Resistance Welding | Not Recommended |

| | | Fabrication Technique | Suitability | Capacity for Being Cold Worked | Poor | Capacity for Being Hot Worked | Fair | Hot Working Temperature | 700 – 800 °C | Annealing Temperature | 425 – 600 °C | Stress Relieving Temperature | 250 – 300 °C | Machinability Rating | 90% of free cutting brass (C36000) | Polishing/Electroplating Finish | Good |

|

Mechanical PropertiesAS1567, Wrought Rods, Bars & Sections Temper | .2% Proof Stress | Tensile Strength | Elongation | Hardness | M (as manufactured) | MPa | MPa | % | HV | | Typical Values | 215 | 495 | 15 | 150 | | Minimum | – | 380 | 12 | – |

Available Forms Austral Wright Metals are able to supply this alloy as extruded rods. General Description Free cutting brass is a significantly improved form of 60/40 brass, with excellent free cutting characteristics. It is used in the mass production of brass components on high speed lathes where maximum output and longest tool life are required, and where no further cold forming after machining is needed. The superior machining characteristics of alloy 385 are due to the rapid chill effect of continuous casting, which gives a fine uniform lead distribution without segregation, and suppresses the formation of brittle phases which cause tool wear. The alloy gives: - Superior surface finish without tooling modification

- Improved tool life and reduced tool sharpening

- Cleaner threads with no build-up and no breakage

- Cutting tools previously used with a negative rake can be modified to zero top rake

Typical applications are nuts, bolts & screw threads Physical Properties| Property | Metric Units | Imperial Units | Melting Point (Liquidus) | 890°C | 1635°F | Melting Point (Solidus) | 875°C | 1610°F | | | | Density | 8.47 gm/cm³ @ 20°C | 0.306 lb/in³ @ 68°F | Specific Gravity | 8.47 | 8.47 | | | | Coefficient of Thermal Expansion | 20.9 x 10 -6 / °C (20-300°C) | 11.0 x 10 -6 / °F (68-392°F) | Themal Conductivity | 121 W/m. °K @ 20°C | 70 BTU/ft³/ft/hr/°F @ 68°F | Thermal Capacity (Specific Heat) | 377 J/kg. °K @ 20°C | 0.09 BTU/lb/°F @ 68°F | | | | Electrical Conductivity | 0.162 microhm?¹.cm?¹ @ 20°C | 28% IACS | Electrical Resistivity | 6.16 microhm.cm @ 20°C | 38 ohms (circ mil/ft)@ 68°F | | | | Modulus of Elasticity (tension) | 97 GPa @ 20°C | 14.2 x 10 6 psi @ 68°F | Modulus of Rigidity (torsion) | 37 GPa @ 20°C | 5.3 x 10 6 psi @ 68°F | Poisson’s Ratio | 0.32 | 0.32 |

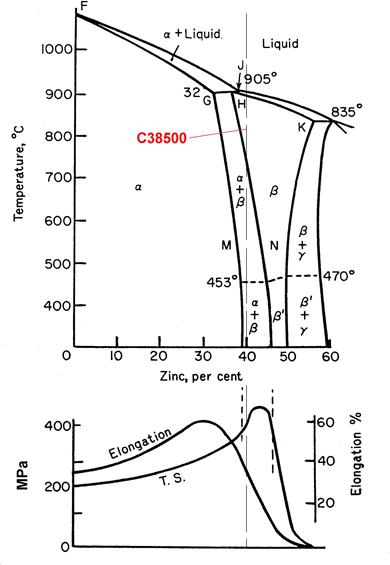

Phase Diagram & Mechanical Properties

Corrosion ResistanceAlloy 385 has good corrosion resistance to weathering and fair resistance to many waters. Alloy 385 should not be used in contact with ammonia, ammonia compounds or amines, as it may suffer stress corrosion cracking. Please consult Austral Wright Metals for specific advice on your application. |