Nickel Alloy & High Performance Alloys Datasheet

Nickel Alloys & High Performance Alloys – DatasheetsAustral Wright Metals has a history of over 75 years in the nickel alloy and high performance alloys business as one of the industry’s leading suppliers. The High Performance Materials group sources a wide range of non ferrous & specialised alloys to meet critical applications. The group also works with its customers on major projects such as new plant as well as maintenance & expansion of existing plants. We have the capability of supplying fully fabricated products as well as semi fabs. We carry as extensive range of stocks of these specialised alloys in our warehouse.

Table of Contents |

Problem Solving Alloys from Austral Wright Metals |

This section contains a few examples of product data sheets we have available. For these and may other product data sheets please visit our web site www.australwright.com.au or contact your local sales office. |

|

| * Registered Trade Names |

Alloy C=276 UNS N10276 |

| Alloy C-276 is a versatile nickel molybdenum chromium tungsten alloy with outstanding corrosion resistance in a wide range of severe media. It resists corrosion attack of many types, and is often used in severe environments of variable or undefined aggressiveness. |

|

|

Typical ApplicationsChemical plant, pollution control, pulp & paper production, waste treatment, process vessels & piping, heat exchangers, stack liners, ducts, dampers, scrubbers, fans & housings. DescriptionAlloy C-276 is a Ni-Mo-Cr-W alloy developed for outstanding resistance to corrosion. It has good strength and excellent ductility, good weldability and fabrication ability, and is tough at all temperatures. It is highly resistant to oxidising atmospheres up to 1040ºC, and to pitting and stress corrosion attack. C-276 is readily welded, and generally does not require post weld heat treatment. Corrosion ResistanceC-276 is outstanding in resisting general corrosion, stress corrosion cracking, pitting and crevice corrosion even in severe environments. It has a low carbon content, and resists intergranular corrosion in the as-welded condition. |

Corrosion Rates in Laboratory Tests in Various Media |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| aTest Duration of 168 h except as noted. b Test Duration of 24 h. |

Maximum Pitting or Crevice Attack, mm, in Flue Gas Desulphuriser Scrubby Slurry |

|

| 6 month exposure at 52°C, pH 5.5, 5000 ppm chloride. bPerforated. Please consult Austral Wright Metals for your specific corrosion application. |

Pressure VesselsAS1210 & ASME Boiler & Pressure Vessel Codes pre-qualify C-276 for use in pressure vessels up to 675ºC. |

|

FabricationC-276 can be readily fabricated, using standard methods for nickel alloys. Hot working is done at 870 – 1230ºC, with all heavy forming above 1090ºC. Cold forming may require intermediate annealing to remove the work hardening developed. MachinabilityC-276 is fairly difficult to machine (group D-2). Sharp tools, slow speeds and deep uninterrupted cuts to remove the work hardened layer are needed. Tools need positive rake angles. |

|

Heat TreatmentC-276 is annealed at 1150 – 1175ºC, cooled by water quenching. |

Physical Properties |

|

ASTM Product Specifications |

|

Monel 400, R=405 UNS N04400 |

| Monel 400 is a versatile nickel copper alloy with good strength and toughness, combined with outstanding corrosion resistance. Monel R-405 is a free cutting version with similar properties. |

|

|

Typical ApplicationsChemical plant, valves and pumps, pump & propeller shafts, marine fixtures and fasteners, electrical components, springs, gasoline & fresh water tanks, petroleum stills, process vessels & piping, boiler feedwater heaters and other heat exchangers, deaerating heaters. DescriptionMonel 400 is a nickel copper alloy with good strength and ductility, good weldability and excellent resistance to corrosion. It is tough over a wide range of temperatures. It is often used in marine applications. Corrosion rates in strongly agitated and aerated sea water are extremely low. The alloy has useful properties to 540ºC in oxidising atmospheres and higher temperatures in reducing conditions. Monel 400 is readily welded and brazed. AvailabilityAustral Wright Metals can supply Monel 400 as plate, sheet and strip, rod and bar, seamless and welded tube and pipe, condenser and heat exchanger tube, welding fittings, forgings and forging billet, wire. Monel R-405 is available as rod and bar.

High Temperature Tensile Properties of Annealed Monel 400

|

Pressure VesselsAS1210 & ASME Boiler & Pressure Vessel Code pre-qualify Monel 400 for use in pressure vessels up to about 475ºC. Corrosion ResistanceMonel 400 is generally more corrosion resistant that both of the major constituents nickel and copper. It is highly resistant to chlorinated solvents, glass etching agents, sulphuric, hydrofluoric and many other acids, and practically all alkalies. The alloy gives excellent service in sea water under high velocity conditions, where resistance to cavitation and erosion are important. Corrosion rates in strongly agitated and aerated sea water are extremely low. It is generally free from chloride stress corrosion cracking, but only annealed material resists stress cracking in the presence of mercury or mercury salts, and in moist, aerated hydrofluoric acid vapour. It should not be used for nitric acid service. Please consult Austral Wright Metals for specific advice on your application. |

|

FabricationMonel 400 can be readily hot worked, with lower forces than many steels. The alloy can easily be cold formed, with forces between those of carbon steel and grade 304 stainless steel. MachinabilityMonel 400 is easy to machine (class B). Sharp tools, slow speeds and deep uninterrupted cuts to remove the work hardened layer are needed. Monel R-405 is a free cutting version of Monel 400, for rapid production in automatic screw machines. Toughness, strength and corrosion resistance are very similar to Monel 400. WeldingMonel 400 is readily welded by GMAW (MIG), GTAW (TIG), SMAW (manual) and SAW processes. Preheat, post heat and post weld heat treatment are not required. The area around the weld must be clean to prevent contamination of the weld pool. Argon shielding gas is used. |

|

Heat TreatmentMonel 400 is annealed at 870–980ºC, cooling rate not critical. Grain growth is rapid in this alloy, so use the lower end of the temperature range and minimal time to retain good strength. Stress relief, if required, is at 540-570ºC. Stress equalising cold worked material at 300ºC markedly increases the proof stress, without affecting other properties. |

Physical Properties |

|

ASTM Product Specifications |

Chemical Composition | Element | % | Element | % |

Nickel | 63.0 min | Manganese | 1.5 max | |

Copper | 27.0 – 33.0 | Silicon | 0.50 max | |

Aluminium | 2.30 – 3.15 | Carbon | 0.18 max | |

Titanium | 0.35 – 0.85 | Iron | 2.0 max | |

Sulphur | 0.010 max |

Specified Minimum | As Hot Rolled | Annealed | Hard | |

0.2% Proof Stress (MPa) | 275 | 195 | 620 | |

Tensile Strength (MPa) | 515 | 485 | 690 | |

Elongation (%) | 25 | 35 | 2 |

Typical Applications

Pump shafts, propeller shafts, doctor blades and scrapers, springs, valve trim, fasteners.

Description

Monel K-500 is a nickel copper alloy with high strength and good ductility, good weldability and excellent resistance to corrosion. It is tough over a wide range of temperatures. It is a precipitation hardening alloy, and a wide range of properties can be obtained by suitable heat treatments.

It is often used in marine applications, particularly for pumps and propeller shafts. Corrosion resistance is substantially matches the excellent properties of Monel 400, except for greater susceptibility to stress corrosion cracking in some aggressive environments in the aged condition.

Availability

Austral Wright Metals can supply Monel K-500 as plate, sheet and strip, rod and bar, tube and pipe, welding fittings, forgings and forging billet, wire.

Pressure Vessels

Monel K-500 is not prequalified by AS1210 or the ASME Boiler & Pressure Vessel Code for use in pressure vessels.

Corrosion Resistance

Monel K-500 is generally more corrosion resistant that both of the major constituents nickel and copper. It is highly resistant to chlorinated solvents, glass etching agents, sulphuric, hydrofluoric and many other acids, and practically all alkalies. The alloy gives excellent service in sea water under high velocity conditions, where resistance to cavitation and erosion are important. Corrosion rates in strongly agitated and aerated sea water are extremely low. It is generally free from chloride stress corrosion cracking, but only annealed material resists stress cracking in the presence of mercury or mercury salts. Stress corrosion cracking in hydrofluoric acid vapours has also been encountered. Monel K-500 should not be used for nitric acid service. Please consult Austral Wright Metals for advice on your specific application.

Equivalent Grade | Country | Body | Grade |

USA | UNS | N05500 | |

France | AFNOR | ||

GB | BS | NA18 | |

Germany | DIN | 2.4375 |

Fabrication

Monel K-500 can be readily hot worked, in the range 870ºC to no higher than 1150ºC. The forging should be water quenched from 790ºC or higher. Care is needed in reheating practice. The alloy can be cold formed, with high forces even in the annealed condition, but ductility is good.

Machinability

Monel K-500 is best to machined when annealed, but can be finish machined when age hardened. During age hardening there is a slight, uniform contraction.

Welding

Monel K-500 is readily welded by GMAW (MIG), GTAW (TIG), SMAW (manual) and SAW processes. Preheat, post heat and post weld heat treatment are not required. The area around the weld must be clean to prevent contamination of the weld pool. Argon shielding gas is used. Welding should be done on annealed material, and the assembly stress relieved before ageing.

| Filler Metal Selection (Self Welds) | Normal Service | Higher Strength | Best Corrosion Resistance | |

| Welding Electrode | Monel WE 190 | Monel WE 190 | Monel WE 190 | |

| Filler Metal | Monel FM 60 | Monel FM 60 | Monel FM 60 | |

| Flux Cored Wire | – | Inco-cored 82DH | – |

Heat Treatment

Adequate softening may be obtained by annealing at 760-870ºC, but best response to subsequent ageing is achieved by annealing at 980ºC for hot finished material and 1040ºC for cold drawn products. Work should be water quenched after annealing. Addition of 2% alcohol to the quench water will minimise oxidation and facilitate pickling. The ageing treatment depends on the properties required, and Austral Wright Metals will be pleased to provide advice.

Physical Properties

Property | at | value | unit |

Density | 20ºC | 8,440 | kg/m3 |

Melting Range | 1315-1350 | ºC | |

Modulus of Elasticity | |||

Tension | 20ºC | 179 | GPa |

Torsion | 20ºC | 65.5 | GPa |

Poisson’s Ratio | 20ºC | 0.32 | |

Specific Heat | 20ºC | 419 | J/kg . ºC |

Mean Coefficient of Expansion | 20ºC | 13.7 | x 10-6 / ºC |

Thermal Conductivity | 20ºC | 17.5 | W / m . ºC |

Curie Temperature | -65 | ºC | |

Electrical Resistivity | 20ºC | 0.615 | micro-ohm . m |

Electrical Conductivity | 20ºC | 2.8 | % IACS |

ASTM Product Specifications

Specification | Title |

B865 | Precipitation Hardening Nickel-Copper-Aluminium Alloy (UNS N05500) Bar, Rod, Wire, Forgings, and Forging Stock |

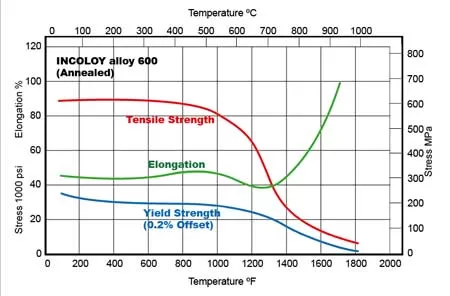

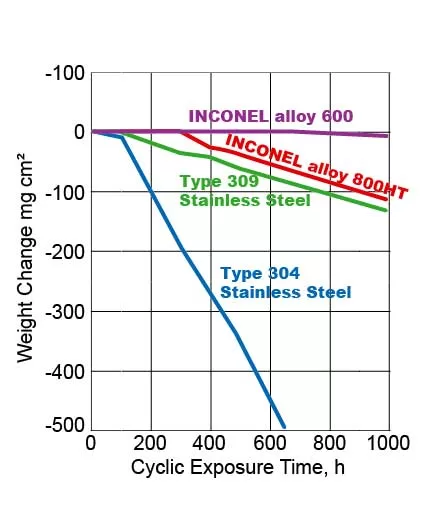

Inconel 600 UNS N06600

Inconel 600 is a solid solution nickel chromium alloy for high temperature applications. Inconel 600 has good mechanical strength and can be used from cryogenic temperatures to 1200ºC. It also has good corrosion resistance due to the high nickel content in combination with chromium.

Chemical Composition | Element | % | Element | % |

Nickel | 72.0 min |

| 1.00 max | |

Chromium | 14.0 – 17.0 | Silicon | 0.50 max | |

Iron | 6.00 – 10.00 | Sulphur | 0.015 max | |

Carbon | 0.15 max | Copper | 0.50 max |

Specified Minimum | Specified Minimum | |

Yield Stress (MPa) | 240 | |

Tensile Strength (MPa) | 550 | |

Elongation (%) | 30 |

Typical Applications

Heat treating muffles and retorts, heat treating baskets, chlorination equipment to 540ºC, pulp mill alkaline digesters. Other applications include heaters, stills, bubble towers, condensers for processing fatty acids, evaporator tubes, tube sheets and flaking trays for sodium sulphite manufacture, springs primary water pumping.

Availability

Austral Wright Metals can supply Inconel 600 as plate, sheet and strip, rod and bar, seamless and welded tube and pipe, welding fittings, forgings, forging billet, wire.

High Temperature Applications

Inconel 600 has excellent resistance to oxidation at high temperatures. It is the standard material for nitriding containers because of its resistance to nitrogen at high temperatures. It also has good resistance to carburisation. Inconel 600 will resist attack by sulphur compounds at moderate temperatures, but is subject to sulphidation at higher temperatures. Lubricants containing molybdenum disulphide should not be used above 425ºC. Inconel 600 is not embrittled by long exposures at high temperature.

Pressure Vessels

Inconel 600 is approved under AS1210 and ASME boiler and pressure vessel code Sections I (Code case 1827), III, VIII for temperatures up to 650ºC.

Corrosion Resistance

Inconel 600 has good corrosion resistance to many media. In feed water systems it is practically free of corrosion. It resists flowing sea water, but will corrode in stagnant sea water. The alloy has fair resistance to sulphuric acid at room temperature, but should not be used in this application at elevated temperatures. Resistance to hydrochloric acid is similar to sulphuric acid. The alloy has excellent resistance to phosphoric acid at room temperature in all concentrations, but is rapidly attacked at elevated temperature. Inconel 600 is practically free from chloride ion stress corrosion cracking. Please consult Austral Wright Metals for advice on your specific application.

Oxidation Resistance

Inconel 600 has good resistance to oxidation at high temperature. It out performs all other alloys for resistance to nitridation in cracked ammonia. It should not be used in sulphur containing atmospheres at high temperature, particularly if the conditions are reducing. It resists dry chlorine and hydrochloric acid gas at moderate temperatures.

Fabrication

Inconel 600 can be hot forged. The surface should be clean before heating. Solution annealing after forging is normal. Inconel 600 is readily cold formed by standard processes and equipment. Work hardening in cold forming may require intermediate anneal.

Machinability

Inconel 600 is reasonably easy to machine (class “C” alloy). Heavy machines, sharp tools, slow speeds and deep cuts to remove the work hardened layer are needed.

Equivalent Grade | Country | Body | Grade |

USA | UNS | N06600 | |

France | AFNOR | NC 15 Fe | |

GB | BS | NA14 | |

Germany | DIN | 2.4816 |

Welding

Inconel 600 is readily welded by the SMAW (manual), GMAW (MIG), GTAW (TIG) and SAW processes. Preheat, post heat and post weld heat treatment are not needed. Contamination of the weld pool should be avoided. Inconel welding electrode 182 or Inconel filler metal 82 are normally used as welding consumables. Argon is used as the shielding gas.

| Welding Consumables | Normal Service | Higher Strength | Best Corrosion Resistance | |

| Welding Electrode | Inconel WE 182 | Inconel WE 182 | Inconel WE 182 | |

| Filler Metal | Inconel FM 82 | Inconel FM 82 | Inconel FM 82 | |

| Flux Cored Wire | Inco Cored 82DH | Inco Cored 82DH | Inco Cored 82DH |

Heat Treatment

Annealing at 1010ºC for 15 minutes softens Inconel 600. Solution heat treatment is done at 1090 – 1150ºC to dissolve carbides. Care should be taken with heat treatment as it affects corrosion resistance and high temperature properties.

Physical Properties

Property | at | value | unit |

Density | 20ºC | 8,470 | kg/m3 |

Melting Range | 1354-1413 | ºC | |

Modulus of Elasticity | |||

Tension | 22ºC | 214 | GPa |

Torsion | 22ºC | 80.8 | GPa |

Poisson’s Ratio | 22ºC | 0.324 | |

Specific Heat | 20ºC | 444 | J/kg . ºC |

Mean Coefficient of Expansion | 20ºC | 10.4 | x 10-6 / ºC |

Thermal Conductivity | 20ºC | 14.9 | W / m . ºC |

Curie Temperature | -192 | ºC | |

Electrical Resistivity | 20ºC | 1.03 | micro-ohm . m |

Relative Permeability | 200Oe | 1.010 |

ASTM Product Specifications

Specification | Title |

B163 | Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes |

| B166 | Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06690, N06025, and N06045)* and Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617) Rod, Bar, and Wire |

| B167 | Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06690, N06025, and N06045)* Seamless Pipe and Tube |

| B168 | Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06690, N06025, and N06045) and Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617) Plate, Sheet, and Strip |

| B366 | Factory-Made Wrought Nickel and Nickel Alloy Fittings |

| B516 | Welded Nickel-Chromium-Iron Alloy (UNS N06600), UNS N06025, and UNS N06045 Tubes |

| B517 | Welded Nickel-Chromium-Iron-Alloy (UNS N06600), UNS N06025, and UNS N06045 Pipe |

| B564 | Nickel Alloy Forgings |

| B751 | General Requirements for Nickel and Nickel Alloy Welded Tube |

| B775 | General Requirements for Nickel and Nickel Alloy Welded Pipe |

Inconel 604 UNS N06601

Inconel 601 is a solid solution nickel chromium heat resisting alloy which gives outstanding performance at temperatures up to about 1200ºC. Inconel 601 also has good aqueous corrosion resistance due to the high nickel content in combination with chromium. Strength and toughness are good, and are retained during extended service at high temperature.

Chemical Composition | Element | % | Element | % |

Nickel | 58.0 – 63.0 |

| 1.5 max | |

Chromium | 21.0 – 25.0 | Silicon | 0.5 max | |

Iron | ~ 16 | Sulphur | 0.015 max | |

Aluminium | 1.0 – 1.7 | Copper | 1.0 max | |

Carbon | 0.10 max |

Specified Minimum | Specified Minimum | |

0.2% Proof Stress (MPa) | 205 | |

Tensile Strength (MPa) | 550 | |

Elongation (%) | 30 |

Typical Applications

Thermal processing equipment – baskets, trays, fixtures, radiant tubes, muffles, retorts, flame shields, woven wire conveyers, burner nozzles and electrical resistance heating wires. Other applications include thermocouple protection tubes, process heaters, condenser tubes, catalyst supports in nitric acid manufacture, exhaust systems in gasoline engines and combustion chambers, superheater tube supports and ash handling in power generation.

Description

Inconel 601 is a solid solution nickel chromium alloy for high temperature heat resistance. It has excellent oxidation resistance. Inconel 601 also has good resistance to carburising but should not be used in atmospheres containing sulphur, particularly reducing sulphur. Inconel 601 has good resistance to nitriding in dissociated ammonia, and is only outperformed by Inconel 600 in this application. Inconel 601 has good strength, ductility and toughness, and can be used at cryogenic temperatures.

Availability

Austral Wright Metals can supply Inconel 601 as plate, sheet and strip, rod and bar, seamless tube and pipe, wire, forgings and forging stock.

Oxidation Resistance

Inconel 601 has outstanding resistance to high temperature oxidation. It resists oxidation and spalling at temperatures as high as 1260ºC. The protective oxide coating resists scaling even under severe conditions, and the alloy also has good resistance to carburisation and nitridation. Its resistance to sulphur is poor and it should not be used in atmospheres containing sulphur, particularly reducing sulphur.

Pressure Vessels

Inconel 601 is qualified for use in pressure vessels in ASME Section VIII (Code case 1500) to 480ºC. It is not pre qualified in AS1210.

Corrosion Resistance

Inconel 601 has excellent corrosion resistance to the mineral acids, similar to Inconel 600. Inconel 601 has good resistance to sodium hydroxide solutions and because of the high nickel content good resistance to chloride stress corrosion cracking. As with austenitic stainless steels Inconel 601 can be sensitised to intergranular corrosion in some aggressive media after heating in the temperature range 540 – 760ºC. Please consult Austral Wright Metals for your specific application.

Fabrication

Inconel 601 is readily hot worked. Inconel 601 must be clean before heating is commenced and should not be heated in an atmosphere high in sulphur. This alloy can be cold formed similarly to austenitic stainless steel. Work hardening in cold forming may require intermediate annealing.

Machinability

Inconel 601 as a ‘C’ class alloy is fairly difficult to machine. Heavy machines, sharp tools, slow speeds and deep cuts to remove the work hardened layer are needed.

Welding

Inconel 601 is readily weldable by the SMAW (manual), GMAW (MIG), GTAW (TIG) and SAW processes. Preheat or post weld heat treatment are not needed. Care must be taken to avoid contamination of the weld pool. Argon is used as the shielding gas.

Equivalent Grade | Country | Body | Grade |

USA | UNS | N06601 | |

France | AFNOR | NC 23 FeA | |

GB | BS | – | |

Germany | DIN | 2.4851 |

| Welding Consumables | Normal Service | Higher Strength | Best Corrosion Resistance | |

| Welding Electrode | Inconel WE 182 | Inconel WE 117 | N/A | |

| Filler Metal | Inconel FM 82 | Inconel FM 617 | Inconel FM 601 | |

| Flux Cored Wire | Inco Cored 82DH | N/A | N/A |

Heat Treatment

Inconel 601 is solution annealed at 1100 – 1180ºC, and cooled quickly so as to avoid sensitisation to intergranular corrosion. Annealing time should be short to avoid excessive grain growth.

Physical Properties

Property | at | value | unit |

Density | 20ºC | 8,110 | kg/m3 |

Melting Range | 1360-1411 | ºC | |

Modulus of Elasticity | |||

Tension | 20ºC | 207 | GPa |

Torsion | 20ºC | 81.2 | GPa |

Poisson’s Ratio | 20ºC | 0.272 | |

Specific Heat | 20ºC | 448 | J/kg . ºC |

Mean Coefficient of Expansion | 20ºC | 13.8 | x 10-6 / ºC |

Thermal Conductivity | 20ºC | 11.2 | W / m . ºC |

Curie Temperature | -192 | ºC | |

Electrical Resistivity | 20ºC | 1190 | micro-ohm . m |

ASTM Product Specifications

Specification | Title |

| B166 | Nickel Chromium Iron and Nickel Chromium Molybdenum Rod, Bar and Wire |

| B167 | Nickel Chromium Iron Seamless Pipe |

| B168 | Nickel Chromium Iron Alloys and Nickel Chromium Cobalt Molybdenum Alloy Plate, Sheet and Strip |

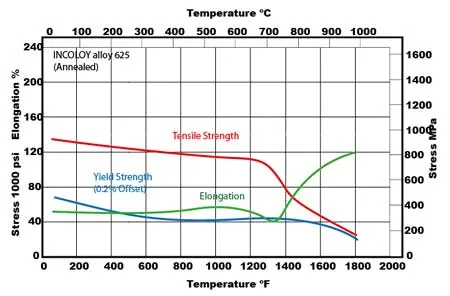

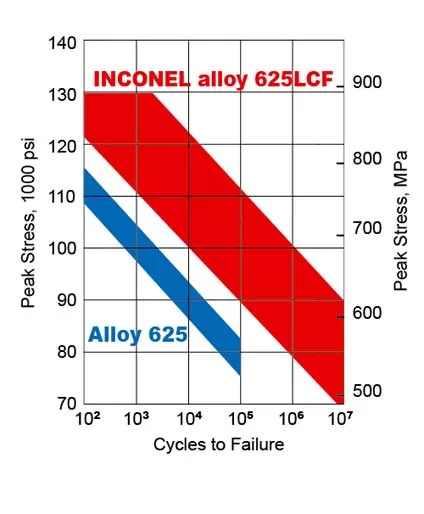

Inconel 625, 625LCF UNS N06625

Inconel 625 is a nickel chromium molybdenum alloy with high strength at elevated temperatures, combined with outstanding corrosion resistance. It has the best all-round combination of strength and corrosion resistance of the Inconel family of alloys. It is pre-qualified for use in pressure vessels up to 815ºC. Inconel 625LCF is a special quality of the alloy for use in bellows.

Chemical Composition | Element | % | Element | % |

| 58.0 min |

| 0.03 max | |

Chromium | 20.0 – 23.0 | Nitrogen (Inconel 625LCF) | 0.02 max | |

Molybdenum | 8.0 – 10.0 | Silicon | 0.15 max | |

Niobium + Tantalum | 3.15 – 4.15 | Phosphorus | 0.015 max | |

Iron | 5.0 max | Sulphur | 0.015 max | |

Cobalt (if determined) | 1.0 max | Aluminium | 0.40 max | |

Manganese | 0.50 max | Titanium | 0.40 max | |

Carbon (Inconel 625) | 0.10 max |

Specified Minimum | Grade 1 (Annealed) | Grade 2 (Solution Annealed) | ||

Diameter | Up to 102mm | 103 to 254mm | All | |

0.2% Proof Stress (MPa) | 415 | 345 | 275 | |

Tensile Strength (MPa) | 830 | 760 | 690 | |

Elongation (%) | 30 | 25 | 30 | |

Grade 2 – solution annealed at 1090ºC (min), with or without stabilise anneal at 980ºC (min) for sensitisation resistance.

Typical Applications

Chemical plant, bellows, submerged marine components, weld overlays, power station scrubber systems, general corrosion applications for aggressive environments, combustion and ducting systems, fuel nozzles, after burners, aerospace components.

Description

Inconel 625 is a nickel chromium molybdenum solid solution strengthened high strength alloy, which retains strength to high temperatures. It is used from cryogenic temperatures to 980ºC. Fatigue strength is outstanding, particularly as the bellows grade, Inconel 625LCF, where carbon, silicon and nitrogen are controlled to low levels. The alloys have good oxidation resistance and resist corrosion by many corrosive media. When exposed to high temperature for long periods, Inconel 625 will age harden due to the niobium, titanium and aluminium additions. When aged there is an increase in strength and some loss of ductility and toughness.

Availability

Austral Wright Metals can supply Inconel 625 as plate, sheet and strip, rod and bar, seamless and welded tube and pipe, welding fittings, forgings and forging billet. Inconel 625LCF is available as annealed sheet and strip from 0.13 mm to 2.54 mm thick, up to 1219 mm wide.

Pressure Vessels

AS1210 prequalifies Inconel 625 up to 625ºC as flat products, and 650ºC as bar and forgings. ASME Boiler & Pressure Vessel Code, Section VIII (Code Case 1409-5) allows annealed material to be used to 650ºC, solution treated to 815ºC.

Corrosion Resistance

Inconel 625 has a corrosion resistance to many environments. In mild environments such as atmosphere, fresh water and sea water, neutral salts and alkaline media there is almost no attack. In more aggressive media nickel and chromium resist oxidising attack, while nickel and molybdenum resist reducing environments. Molybdenum provides exceptional resistance to pitting and crevice corrosion, and niobium stabilises against sensitisation and intergranular corrosion. The nickel content makes Inconel 625 essentially free from chloride ion stress corrosion cracking. Inconel 625 also has excellent corrosion fatigue properties. Please consult Austral Wright Metals for specific advice on your application.

Corrosion Rates

(mm/year) in a municipal waste incinerator at 650 – 700ºC after 2050 hours & 6750 hours

| Inconel 625 | Inconel 800 | Incoloy 825 | SS 310 | SS 316 | SS 446 | |

2050 Hours | 7 | 35 | 127 | 48 | 71 | 82 |

6750 Hours | 13 | destroyed | destroyed | 89 | destroyed | 54 |

Equivalent Grade | Country | Body | Grade |

USA | UNS | N06625 | |

France | AFNOR | NC 22 D Nb | |

GB | BS | NA21 | |

Germany | DIN | 2.4856 |

Fabrication

Inconel 625 was developed for hot strength, so resists hot working. It is ductile and can be readily hot worked with high forces. The alloy can also be cold formed with heavy forces. Intermediate annealing may be needed.

Machinability

Inconel 625 is difficult to machine (class D-2). Heavy machines, sharp tools, slow speeds and deep uninterrupted cuts to remove the work hardened layer are needed.

Welding

Inconel 625 is readily welded by GMAW (MIG), GTAW (TIG), SMAW (manual) and SAW processes. Preheat, post heat and post weld heat treatment are not required. The area around the weld must be clean to prevent contamination of the weld pool. Argon shielding gas is used.

| Welding Consumables | Normal Service | Higher Strength | Best Corrosion Resistance | |

| Welding Electrode | Inconel WE 112 | N/A | Inco Weld WE 686CPT | |

| Filler Metal | Inconel FM 625 | Inco Weld FM725NDUR | Inco Weld WE 686CPT | |

| Flux Cored Wire | Inco Cored 625DH | N/A | N/A |

Heat Treatment

Inconel 625 is annealed at 925–1040ºC, cooling rate not critical. Solution anneal at 1090–1200ºC. Stress relief, if required, is at 590–760ºC, or up to 870ºC for complete relief.

Physsical Properties

(Inconel 625 and 625LCF, Annealed)

Property | at | value | unit |

Density | 20ºC | 8,440 | kg/m3 |

Melting Range | 1290-1350 | ºC | |

Modulus of Elasticity (Annealed) | |||

Tension | 20ºC | 208 | GPa |

Torsion | 20ºC | 81.4 | GPa |

Poisson’s Ratio | 20ºC | 0.278 | |

Modulus of Elasticity (Solution Treated) | |||

Tension | 20ºC | 205 | GPa |

Torsion | 20ºC | 77.9 | GPa |

Poisson’s Ratio | 20ºC | 0.312 | |

Specific Heat | 20ºC | 410 | J/kg . ºC |

Mean Coefficient of Expansion | 20ºC | 12.8 | x 10-6 / ºC |

Thermal Conductivity | 20ºC | 9.8 | W / m . ºC |

Curie Temperature | < -196 | ºC | |

Electrical Resistivity | 20ºC | 1.29 | micro-ohm . m |

Electrical Conductivity | 20ºC | 1.3 | % IACS |

ASTM Product Specifications

Specification | Title |

| B366 | Factory-Made Wrought Nickel and Nickel Alloy Fittings |

| B443 | Nickel-Chromium-Molybdenum-Columbium Alloy (UNS N06625) Plate, Sheet, and Strip |

| B444 | Nickel-Chromium-Molybdenum-Columbium Alloys (UNS N06625) Pipe and Tube |

| B446 | Nickel-Chromium-Molybdenum-Columbium Alloy (UNS N06625) Rod and Bar |

| B564 | Nickel Alloy Forgings |

| B704 | Welded UNS N06625 and UNS N08825 Alloy Tubes |

| B705 | Nickel-Alloy (UNS N06625 and N08825) Welded Pipe |

| B751 | General Requirements for Nickel and Nickel Alloy Welded Tube |

Titanium Grade 2 UNS R50400 |

Titanium grade 2 is commercially pure titanium. It has outstanding corrosion resistance and useful strength (similar to austenitic stainless steels) at low density. It has good weldability and is easily formable. It is the most commonly used grade of titanium.

Typical Applications

Most of the applications of this grade are in the chemical industries. The most common uses are reactor autoclaves, piping and fittings, valves, heat exchangers and condensers.

Chemical Composition – ASTM B338 | Element | % | Element | % |

| Balance |

| 0.30 max | |

Nitrogen | 0.03 max | Oxygen | 0.25 max | |

Carbon | 0.08 max | Residuals, each | 0.1 max | |

Hydrogen | 0.015 max | Residuals, total | 0.4 max |

Specified Minimum Mechanical Properties – ASTM B338 | Annealed | |

0.2% Proof Stress (MPa) | 275 | |

Tensile Strength (MPa) | 690 | |

Elongation (%) | 30 |

Description

Titanium grade 2 is a commercially pure grades. It has excellent corrosion resistance in oxidising conditions, and is effectively immune from stress corrosion cracking, pitting corrosion and crevice corrosion in chloride solutions below 70ºC. Titanium grade 2 is widely used in heat exchangers, where despite the low thermal conductivity of titanium the efficiency of heat transfer is high due to good strength, high resistance to erosion corrosion and the fouling resistance of the hard, smooth surface.

At room temperature grade 2 is an alpha alloy. It transforms to beta phase at 913 ±15ºC, and the alpha phase returns on cooling 890 ±15ºC.

Titanium is reactive, with a very high affinity for oxygen, which forms a skin of very stable and highly adherent oxide. The skin gives excellent corrosion resistance, despite the reactivity of the metal. The oxide layer forms spontaneously and rapidly on exposure to the atmosphere. However, when new parent metal is exposed to anhydrous conditions or in the absence of air, rapid corrosion may occur. Care should also be taken if titanium is to operate in contact with hydrogen, as hydrogen embrittlement from hydride formation can increase strength, with loss of ductility.

Availability

Austral Wright Metals can supply this alloy as plate, sheet and strip, rod and bar, seamless and welded pipe, weld fittings, seamless and welded tube, forging billet and forgings. It is widely used as tube in condensers and heat exchangers.

Pressure Vessels

AS1210 & ASME Boiler & Pressure Vessel Code pre-qualify titanium 2 for use in pressure vessels up to 300ºC. AS4041 Pressure Piping qualifies the alloy to 325ºC.

Corrosion Resistance

Titanium has excellent resistance to general corrosion, with low or negligible loss rates in many media. See Austral Wright Metals data sheet “Corrosion of Titanium and alloys” for more detail. The table at the end of this data sheet illustrates the excellent erosion corrosion performance of grade 2 in sea water.

Physical Properties

Property | at | value | unit |

Density | 20ºC | 4,507 | kg/m3 |

Melting Range | 1668 ±10 | ºC | |

Modulus of Elasticity | |||

Tension | 20ºC | 103 | GPa |

Specific Heat | 20ºC | 519 | J/kg . ºC |

Mean Coefficient of Expansion | 20ºC | 8.41 | x 10-6 / ºC |

Thermal Conductivity | 20ºC | 11.4 | W / m . ºC |

Electrical Resistivity | 20ºC | 0.420 | micro-ohm . m |

Erosion Corrosion Rates of Unalloyed Titanium, Grade 2

| Location | Flow Rate (m/sec) | Type of Test | Test Duration (mths) | Erosion Corrosion Rate (mm/year) |

Brixham Sea | 9.8 | Model Condenser | 12 | 0.003 |

Kure Beach, NC | 1 | Ducting | 54 | 7.5 x 10-7 |

Kure Beach, NC | 8.5 | Rotating Disc | 2 | 1.2 x 10-4 |

Kure Beach, NC | 9 | Micarta Wheel | 2 | 2.8 x 10-4 |

Kure Beach, NC | 7.2 | Jet Impingement | 1 | 5.0 x 10-4 |

Wrightsville Beach, NC | 1.3 | – | 6 | 1.0 x 10-4 |

Wrightsville Beach, NC | 9 | Micarta Wheel | 2 | 1.8 x 10-4 |

Mediterranean Sea | 7.2 | Jet Impingement | 0.5 | 0.5 mg/day |

Dead Sea | 7.2 | Jet Impingement | 0.5 | 0.5 mg/day |

Fabrication

Titanium grade 2 is forged by conventional processes within the narrow temperature range 815 – 900ºC. Titanium and its alloys generally are more difficult to forge than both aluminium and alloy steels, due to the narrow temperature range, and high strain rate and temperature dependence of strength. Hot forging leaves a thick, extremely hard layer of titanium oxide on the surface, called “alpha case”. It is usually removed by pickling in a mixture of nitric and hydrofluoric acids. As supplied, titanium alloys are usually annealed, and can be readily cold formed in conventional machines using standard methods. When cold formed the alpha case does not form and pickling is not needed, except to remove embedded carbon steel pickup, which can cause pitting corrosion.

Machinability

Titanium grade 2 is readily machinable by conventional methods. It is similar to austenitic stainless steels for machinability. Like stainless steel, titanium has a low thermal conductivity and heat dissipation is poor, so generous use of coolant is recommended. Sharp tools are essential. Cuts should be deep and continuous, with low cutting speeds.

Welding

Titanium grade 2 is readily weldable by GMAW and GTAW processes. Preheat or post weld heat treatment are not needed. The area immediately surrounding the welds must be CLEAN, free from all grease and shop dirt, including pencil marks. Abrasive cleaning can be used, or solvent cleaning or pickling with a mixture of nitric and hydrofluoric acids. A trailing gas shield must be applied to all areas above 450ºC in addition to the normal welding torch gas shield, to prevent heavy oxidation during cooling. Matching filler metal to AWS ERTi-2 is used. The gas shield must be low in hydrogen, oxygen and nitrogen, all of which readily dissolve in titanium and cause embrittlement.

Heat Treatment

Titanium grade 7 is annealed at 650 – 760ºC, still air cooled. Pickling to remove the alpha case may be needed before further fabrication or machining. Stress relief at 480 – 595ºC, air cooled, may be required to improve dimensional stability for critical components.

ASTM Product Specifications

Specification | Title |

| B265 | Titanium and Titanium Alloy Strip, Sheet and Plate |

| B381 | Titanium and Titanium Alloy Forgings |

| B348 | Titanium and Titanium Alloy Bars and Billets |

| B337 | Seamless and Welded Titanium and Titanium Alloy Pipe |

| B338 | Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers |

| B363 | Seamless and Welded Unalloyed Titanium and Titanium Alloy Welding Fittings |

| B367 | Titanium and Titanium Alloy Castings |

Titanium Grade 12 UNS R53400

Titanium Grade 12 has outstanding corrosion resistance and a combination of high strength and low density, with good ductility. Small additions of nickel and molybdenum have been made to this alloy resulting increase in corrosion resistance and high strength. It is particularly suitable for use in mildly reducing conditions, or where conditions vary from oxidising to reducing. It is particularly resistant to crevice corrosion in hot brines.

Chemical Composition – ASTM B265 | Element | % | Element | % |

| Balance |

| 0.30 max | |

Nitrogen | 0.03 max | Oxygen | 0.25 max | |

Carbon | 0.08 max | Molybdenum | 0.2 – 0.4 | |

Hydrogen | 0.015 max | Nickel | 0.6 – 0.9 | |

Residuals, each | 0.1 | Residuals, total | 0.4 |

Specified Minimum Mechanical Properties – ASTM B265 | Annealed | |

0.2% Proof Stress (MPa) | 345 | |

Tensile Strength (MPa) | 483 | |

Elongation (%) | 18 |

Typical Applications

Many of the applications of grade 12 titanium are in the chemical industries. The common uses in Australia are in chemical processing, where titanium grade 12 is used for reactor autoclaves, piping and fittings, valves, heat exchanges and condensers.

Description

Titanium Grade 12 is a highly corrosion resistant alloy containing small additions of nickel and molybdenum, which enhance corrosion resistance and increase the strength of the alloy to give better mechanical properties than the commercially pure grades. It is used in mildly reducing or fluctuating conditions. In particular, it is used instead of the commercial purity grades (e.g.grade 2) for better resistance to crevice corrosion in hot brines, and where the extra strength allows the use of lighter sections.

At room temperature it is an alpha alloy, and may contain minor amounts of beta phase. It transforms to beta phase at 890ºC ± 15ºC

Titanium is reactive, and has a very high affinity for oxygen, which forms a skin of very stable and highly adherent oxide. The skin gives excellent corrosion resistance, despite the reactivity of the metal. The oxide layer forms spontaneously and on exposure to the atmosphere. However, when new parent metal is exposed to anhydrous conditions or in the absence of air, rapid corrosion may occur. Care should also be taken if titanium is to operate in contact with hydrogen, as hydrogen embrittlement from hydride formation can increase strength, with loss of ductility.

Availability

Austral Wright Metals can supply titanium 12 as plate, sheet and strip, rod and bar, seamless and welded pipe, weld fittings, seamless and welded tube, forging billet and forgings.

Pressure Vessels

AS1210 & ASME Boiler & Pressure Vessel Code pre-qualify Titanium 12 for use in pressure vessels up to 300ºC.

Corrosion Resistance

Titanium alloys are usually used in Australia for their excellent corrosion resistance, especially to chloride solutions. The small additions of nickel and molybdenum to grade 12 titanium give a more corrosion resistant metal than the commercial purity grade 2 alloy, with a marked increase in strength. The overall corrosion resistance of this grade is not as good as the palladium alloyed lean grade 7, except for resistance to crevice corrosion in hot chloride solutions. Titanium has excellent resistance to general corrosion, with loss rates of less than 0.04mm/year being typical. The Austral Wright Metals Product Data Sheet “Corrosion of Titanium and Titanium Alloys” or your local office should be consulted more details.

| Environment | Typical Corrosion Rate mm/year | Environment | Typical Corrosion Rate mm/year | Environment | Typical Corrosion Rate mm/year |

Wet Cl2 gas | 0.00089 | 50% Citric Acid | 0.013 | 88-90% Formic Acid | 0-0.56 |

5% NaOCl + 2% NaCl + 4% NaOH† | 0.06 | 10% Sulphamic Acid | 11.6 | 90% Formic Acid‡ | 0.56 |

70% Zinc Chloride | 0.005-0.0075 | 45% Formic Acid | Nil | 10% Oxalic Acid | 104 |

Source: Metals Handbook, vol 2, ASM

Fabrication

Titanium Grade 12 is forged conventionally, within the narrow temperature range 815 – 900ºC. Titanium and its alloys are generally more difficult to forge than both aluminium and alloy steels, due to their high strain rate sensitivity and rapid increase of strength with falling temperature. Hot forging leaves a thick, hard outer layer of titanium oxide on the surface. This layer is called “Alpha Case” and is usually removed by pickling in a mixture of nitric and hydrofluoric acids. As supplied, titanium alloys are usually annealed and pickled, and can be readily cold formed in conventional machines using standard methods. In cold forming the “alpha case” does not form and further pickling is not needed, except to remove any carbon steel embedded in the surface, which can cause pitting corrosion.

Machinability

Titanium Grade 12 is readily machinable by conventional methods. Like stainless steel, titanium has a low thermal conductivity and heat dissipation is inhibited, so copious amounts of coolant should be used. Sharp carbide tools are used. Deep, continuous cuts are best.

Welding

Titanium Grade 12 is readily weldable by GMAW (MIG) and GTAW (TIG) processes. Preheat or post weld heat treatment are not needed. The area to be welded must be CLEAN, free from all grease and shop dirt, including marking pencil marks. A trailing gas shield is used in addition to the normal welding torch gas shield, to prevent heavy oxidation during cooling. Matching filler metal to AWS specification ERTi-12 is used. The gas shield must be low in hydrogen, oxygen and nitrogen, all of which readily dissolve in titanium and cause embrittlement.

Heat Treatment

Titanium Grade 12 is normally supplied in the annealed condition. After fabrication, stress relief at 480 – 595ºC, air cooled, may be required to improve dimensional stability.

Physical Properties

Property | at | value | unit |

Density | 20ºC | 4,507 | kg/m3 |

Melting Range | 1668 ±10 | ºC | |

Modulus of Elasticity | |||

Tension | 20ºC | 103 | GPa |

Specific Heat | 20ºC | 519 | J/kg . ºC |

Mean Coefficient of Expansion | 20ºC | 8.41 | x 10-6 / ºC |

Thermal Conductivity | 20ºC | 11.4 | W / m . ºC |

Electrical Resistivity | 20ºC | 0.420 | micro-ohm . m |

ASTM Product Specifications

Specification | Title |

| B265 | Titanium and Titanium Alloy Strip, Sheet and Plate |

| B381 | Titanium and Titanium Alloy Forgings |

| B348 | Titanium and Titanium Alloy Bars and Billets |

| B337 | Seamless and Welded Titanium and Titanium Alloy Pipe |

| B338 | Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers |

Stainless Steel Grades 310, 310S UNS S31000, S31008

Grade 310 is a medium carbon austenitic stainless steel, for high temperature applications such as furnace parts and heat treatment equipment. It is used at temperatures up to 1150ºCin continuous service, and 1035ºCin intermittent service. Grade 310S is a low carbon version of grade 310.

Chemical Composition (AS1449, ASTM A240 – Flat Products) | |||||||

| Carbon | Manganese | Silicon | Phosphorus | Sulphur | Chromium | Nickel | |

| 310 | 0.25 max | 2.00 max | 1.50 max | 0.045 max | 0.030 max | 24.00-26.00 | 19.00-22.00 |

| 310S | 0.08 max | 2.00 max | 1.50 max | 0.045 max | 0.030 max | 24.00-26.00 | 19.00-22.00 |

Mechanical Properties | Annealed | |

0.2% Proof Stress (MPa – min) | 205 | |

Tensile Strength (MPa – min) | 520 | |

Elongation (% – min) | 40 | |

Hardness (HV – max) | 225 |

Typical Applications

Grade 310/310S is used in fluidised bed combustors, kilns, radiant tubes, tube hangers for petroleum refining and steam boilers, coal gasifier internal components, lead pots, thermowells, refractory anchor bolts, burners and combustion chambers, retorts, muffles, annealing covers, saggers, food processing equipment, cryogenic structures.

Description

These grades contain 25% chromium and 20% nickel, making them highly resistant to oxidation and corrosion. Grade 310S is a lower carbon version, less prone to embrittlement and sensitisation in service.

The high chromium and medium nickel content make these steels capable for applications in reducing sulphur atmospheres containing H2S. They are widely used in moderately carburising atmospheres, as encountered in petrochemical environments. For more severe carburising atmospheres other heat resisting alloys should be selected. Grade 310 is not recommended for frequent liquid quenching as it suffers from thermal shock. The grade is often used in cryogenic applications, due to its toughness and low magnetic permeability.

In common with other austenitic stainless steels, these grades cannot be hardened by heat treatment. They can be hardened by cold work, but this is rarely practiced.

Availability

Austral Wright Metals can supply these grades as plate, sheet and strip, bar and rod, seamless tube and pipe, welded tube and pipe, forgings and forging billet, tube and pipe fittings, wire. Corrosion Resistance Grade 310/310S is generally not used for corrosive liquid service, although the high chromium and nickel content give corrosion resistance superior to grade 304. The alloy does not contain molybdenum, so pitting resistance is quite poor. Grade 310/310S will be sensitised to intergranular corrosion after service at temperatures in range 550 – 800ºC. Chloride stress corrosion cracking may take place in corrosive liquids containing chlorides at temperatures exceeding 100ºC.

Heat Treatment

Grades 310/310S have good resistance to oxidation in intermittent service in air up to 1035ºCand 1050ºCin continuous service. The grades are resistant to oxidation, sulphidation and carburisation.

Physical Properties

Property | at | value | unit |

Density | 20ºC | 8,000 | kg/m3 |

Melting Range | 1400-1450 | ºC | |

Modulus of Elasticity | 20ºC | 200 | GPa |

Shear Modulus | 20ºC | 77 | GPa |

Specific Heat | 500 | J/kg . ºC | |

Coefficient of Expansion | 0-100ºC | 15.9 | / ºC |

Coefficient of Expansion | 0-315ºC | 16.2 | / ºC |

Coefficient of Expansion | 0-540ºC | 17.0 | / ºC |

Thermal Conductivity | 100ºC | 14.2 | W / m . ºC |

Electrical Resistivity | 25ºC | 0.78 | micro-ohm . m |

Electrical Conductivity | 25ºC | 1.25 | % IACS |

Poisson’s Ratio | 20ºC | 0.30 | |

Relative Magnetic Permeability | 1.02 |

Pressure Vessels

AS1210, Pressure Vessels, allows the use of grade 310 up to 800ºC.

Fabrication

Grades 310/310S are forged in the temperature range 975 – 1175ºC. Heavy work is carried out down to 1050ºCand a light finish is applied to the bottom of the range. After forging annealing is recommended to relieve all stresses from the forging process. The alloys can be readily cold formed by standard methods and equipment.

Machinability

Grades 310/310S are similar in machinability to type 304. Work hardening can be a problem and it is normal to remove the work hardened layer by using slow speeds and heavy cuts, with sharp tools and good lubrication. Powerful machines and heavy, rigid tools are used.

Welding

Grades 310/310S are welded with matching electrodes and filler metals. The alloys are readily welded by SMAW (manual), GMAW (MIG), GTAW (TIG) and SAW. Electrodes to AWS A5.4 E310-XX and A 5.22 E310T-X, and filler metal AWS A5.9 ER310 are used. Argon is shielding gas.

Preheat and post heat are not required, but for corrosion service in liquids full post weld solution annealing treatment is essential.

Pickling and passivation of the surface to remove high temperature oxides are essential to restore full aqueous corrosion resistance after welding. This treatment is not required for high temperature service, but welding slag should be thoroughly removed.

Heat Treatment

Type 310/310S are solution annealed by heating to temperature range 1040 -1065ºC, holding at temperature until thoroughly soaked, then water quenching.

| Effect of Exposure at 480-650ºC on Room Temperature Toughness and Hardness | ||||

| Temperature ºC | Exposure Time | |||

| 1000 Hours | 10,000 hours | |||

| Charpy Impact | Hardness | Charpy Impact | Hardness | |

| J | HB | J | HB | |

0.00089 | 50% Citric Acid | 0.013 | 88-90% Formic Acid | 0-0.56 |

0.06 | 10% Sulphamic Acid | 11.6 | 90% Formic Acid‡ | 0.56 |

0.005-0.0075 | 45% Formic Acid | Nil | 10% Oxalic Acid | 104 |

0.06 | 10% Sulphamic Acid | 11.6 | 90% Formic Acid‡ | 0.56 |

| Mechanical Properties at Cryogenic Temperatures | ||||

| Temperature ºC | Yield Strength MPa | Tensile Strength MPa | Elongation % | Izod Impact J |

-40 | 269 | 655 | 57 | 149 |

-62 | 276 | 689 | 55 | 149 |

-196 | 510 | 1048 | 54 | 115 |

-252 | 745 | 1213 | 56 | |

Comparision Between Heat Resistant Stainless Steel Grades 253MA & 310/310S |

Introduction

Stainless steels are widely used at elevated temperatures when carbon and low-alloy steels do not provide adequate corrosion resistance and/or sufficient strength.

Corrosion resistance is often the first criterion used to select stainless steel for a particular application. However, strength is also a significant factor in a majority of elevated-temperature applications and may even be the key factor governing the choice of stainless steel.

The stainless steels used in applications where high temperature strength is important are sometimes referred to as heat-resistant steels.

The various process stages in the metallurgical industry, right through from ore to the finished, rolled or forged product, usually takes place at high temperatures. The production equipment used in these processes is subjected to intense heat from hot gases or from red-hot or molten materials, which make heavy demands on the construction materials used for that equipment.

The following information is a comparison between two of the more widely used grades of heat-resistant steels, 253MA and 310/310S.

Background

253MA

253MA (UNS S30815) is a grade combining excellent service properties at high temperatures with ease of fabrication. It resists oxidation at temperatures up to 1150°C and can provide good service in carbon, nitrogen and sulphur containing atmospheres.

253MA is not recognised in AS1210 “Pressure Vessels”.

310/310S

Grade 310 (UNS S31000), combining excellent high temperature properties with good ductility and weldability, is designed for high temperature service. It resists oxidation in continuous service at temperatures up to 1150°C provided reducing sulphur gases (eg. H2S) are not present. It is also used for intermittent service at temperatures up to 1040°C.

Grade 310S (UNS S31008) is used when the application environment involves moist corrodents in a temperature range lower than that which is normally considered “high temperature” service. The lower carbon content of 310S reduces its high temperature strength compared to 310, which is recognised in AS1210 “Pressure Vessels”.

Key Proerties

The properties outlined below for each of the grades are specified for flat rolled product (plate, sheet and coil).

| Grade | 253MA | 310 | 310S |

| UNS | S30815 | S31000 | S31008 |

1. Composition

The compositional ranges for 253MA, 310 and 310S, given in Table 1, are specified in ASTM A240/A240M.

Table 1: Composition of 253MA, 310 and 310S

Grade | C | Mn | Si | P | S | Cr | Ni | N | Ce | |

% | % | % | % | % | % | % | % | % | ||

| 253MA (S30815) | Min | 0.05 | – | 1.40 | – | – | 20.0 | 10.0 | 0.14 | 0.03 |

| Max | 0.10 | 0.80 | 2.00 | 0.04 | 0.03 | 22.0 | 12.0 | 0.20 | 0.08 | |

| 310 (S31000) | Min | – | – | – | – | – | 24.0 | 19.0 | – | – |

| Max | 0.25 | 2.00 | 1.50 | 0.045 | 0.03 | 26.0 | 22.0 | – | – | |

| 310S (S31008) | Min | – | – | – | – | – | 24.0 | 19.0 | – | – |

| Max | 0.08 | 2.00 | 1.50 | 0.045 | 0.03 | 26.0 | 22.0 | – | – | |

2. Mechanical Properties

The mechanical properties for 253MA, 310 and 310S, given in Table 2, are specified in ASTM A240/A240M for plate, sheet and strip in the annealed condition.

Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

Rockwell B | Brinell (HB) | ||||

max | max | ||||

253MA (S30815) | 600 | 310 | 40 | 95 | 217 |

310 (S31000) | 517 | 207 | 40 | 95 | 217 |

310S (S31008) | 517 | 207 | 40 | 95 | 217 |

3. Physical Properties

Table 3: Physical Properties of 253MA

Grade | 253MA | |

Density (kg/m3) | 7800 | |

Elastic Modulus (GPa) | 200 | |

Mean Coefficient of Thermal Expansion (µm/m/°C) | 20-100°C | 17.0 |

20-600°C | 18.5 | |

20-1000°C | 19.5 | |

Thermal Conductivity (W/m.K) | at 20°C | 15.0 |

at 600°C | 22.5 | |

at 1000°C | 29.0 | |

Specific Heat (J/kg.K) | 0-100°C | 500 |

Electrical Resistivity | at 20°C | 850 |

Table 4: Physical Properties of 310 and 310S

Grade | 310 & 310S | |

Density (kg/m3) | 7750 | |

Elastic Modulus (GPa) | 200 | |

Mean Coefficient of Thermal Expansion (µm/m/°C) | 0-100°C | 15.9 |

0-649°C | 17.5 | |

0-982°C | 19.1 | |

Thermal Conductivity (W/m.K) | at 100°C | 14.2 |

at 500°C | 18.7 | |

Specific Heat (J/kg.K) | 0-100°C | 500 |

Electrical Resistivity | at 20°C | 720 |

4. Heat Resistance

253MA

Good oxidation resistance in air at temperatures up to 1150°C. At high temperatures the steel quickly forms a thin, highly adherent and elastic oxide. This oxide provides good protection even under cyclic conditions.

This grade performs well in oxidising conditions, but alloys with higher nickel content (such as 310 and 310S) perform much better in carburising (ie reducing) atmospheres.

253MA has good resistance to sulphur-bearing gases in an oxidising atmosphere, even if only traces of oxygen are present. Reducing gases prevent the protective oxide forming.

253MA has high strength at elevated temperatures so is often used for structural and pressure-containing applications at temperatures above about 500°C and up to about 900°C.

253MA will become sensitised in the temperature range 425-860°C, though this is not a problem for high temperature applications, but will result in reduced aqueous corrosion resistance.

310/310S

Good resistance to oxidation in intermittent service in air at temperatures up to 1040°C and 1150°C in continuous service. They have good resistance to thermal fatigue and cyclic heating.

These grades are widely used where sulphur dioxide gas is encountered at elevated temperatures.

Continuous use in 425-860°C range not recommended due to carbon precipitation (which causes sensitisation to intergranular corrosion) if subsequent aqueous corrosion resistance is needed. The grade performs well in temperatures above and below this range.

Grade 310 is generally used at temperatures starting from about 800 or 900°C.

5. Corrosion Resistance

253MA

The high chromium and nitrogen contents give the grade a pitting resistance similar to 316.

253MA has a high carbon content so is highly susceptible to sensitisation from welding or service exposure.

310/310S

The high chromium content, intended to increase high temperature properties, also gives these grades good aqueous corrosion resistance. The Pitting Resistance Equivalent (PRE) is approximately 25, and seawater resistance about 22°C, similar to that of grade 316.

310 and 310S also have a high carbon content so are also susceptible to sensitisation from welding or service exposure. 310 is particularly susceptible due to its much higher carbon content.

Both 253MA and 310/310S are subject to stress corrosion cracking but more resistant than grades 304 or 316.

6. Heat Treatment

253MA

Solution Treatment (Annealing): Heat up to 1050-1150°C and cool rapidly. It is recommended that the material be solution treated after 10-20% cold work to achieve maximum creep strength in service.

253MA cannot be hardened by thermal treatment.

310/310S

Solution Treatment (Annealing): Heat up to 1040-1150°C and cool rapidly for maximum corrosion resistance. This treatment is also recommended to restore ductility after each 1000 hours of service above 650°C, due to long term precipitation of brittle sigma phase.

310 and 310S cannot be hardened by thermal treatment.

7. Welding

253MA

Good weldability by all standard fusion methods, using matching filler materials. AS1554.6 pre-qualifies welding of 253MA with Grade 22.12HT rods or electrodes. Grade 309 fillers can be used if lower creep strength can be tolerated. Pure argon shielding gas should be used.

310/310S

Good characteristics suited to all standard methods. Grade 310S electrodes generally recommended for fusion welding. AS1554.6 pre-qualifies welding of 310 with Grade 310 rods or electrodes.

Alloy Composition Effects

All the commercial purity grades corrode at very low rates while the metal remains in the passive condition. Small contents (< 2 – 3%) of the elements normally present have little effect on the oxide film, and hence on corrosion resistance. However, where the corrosion resistance is marginal (i.e. corrosion rates above about 0.13 mm/year), small amounts of elements such as sulphur and iron accelerate the corrosion rate of the alloy. Minor additions of other elements, such as palladium and nickel, can greatly reduce corrosion under these conditions, and made to highly corrosion resistant alloys such as grade 7.

Weldments of the lean alloys generally show the same corrosion resistance as the unwelded parent metal, without surface treatment. In marginal or active conditions attack may be accelerated at the weld, due to a higher content of impurity elements such as sulphur, iron, oxygen and nitrogen.

General Corrosion

When titanium is fully passive, corrosion rates are typically lower than 0.04 mm/year, due to the highly stable surface protective film. In many environments the film may thicken, which gives interference colours and a slight weight gain. General corrosion may be encountered in reducing acid conditions, particularly at elevated temperatures. In strong and hot reducing acids the titanium oxide film can dissolve, and the unprotected titanium metal be taken rapidly into solution.

Crevice Corrosion

Titanium alloys may suffer crevice corrosion attack by a similar mechanism to that encountered in stainless steels: oxygen depleted reducing acid conditions develop within tight crevices isolated from the bulk corrosion media. Crevice corrosion may be encountered in hot (>70ºC) solutions containing chlorides, bromides, fluorides, iodides or sulphates. It can stem from metal to metal joints such as tube to tubesheet joints or badly designed welds, at gaskets, or at surface deposits.

Pitting Corrosion

Titanium alloys are highly resistant to pitting corrosion, and it is rarely encountered.

Hydrogen Damage

Titanium alloys are widely used in environments containing hydrogen, and where impressed currents or galvanic couples generate hydrogen. Hydrogen embrittlement of the titanium may result due to the formation of titanium hydride precipitates, usually without significant reduction of the performance of the alloy. Embrittlement is loss of ductility and toughness of the alloy.

The surface oxide film is a highly effective barrier to the passage of hydrogen, and only traces of moisture or oxygen are effective in maintaining the oxide film. Hence hydrogen embrittlement can usually be avoided. It is unlikely to be encountered at temperatures below about 80ºC, or at solution pH between 3 and 12.

The usual cause of hydrogen damage is excessive hydrogen charging from an impressed current corrosion protection system, or a galvanic couple (see below) with a more active metal, such as aluminium, zinc or magnesium. Metals which remain passive, such as other titanium alloys, stainless steels, copper alloys and nickel alloys, are unlikely to cause this problem.

Galvic Couples

Titanium rarely suffers accelerated corrosion on coupling with other metals, but it may accelerate the corrosion of a more active metal coupled to it. The rate of attack depends on many factors, including solution chemistry and temperature, and the cathode to anode surface area ratio.

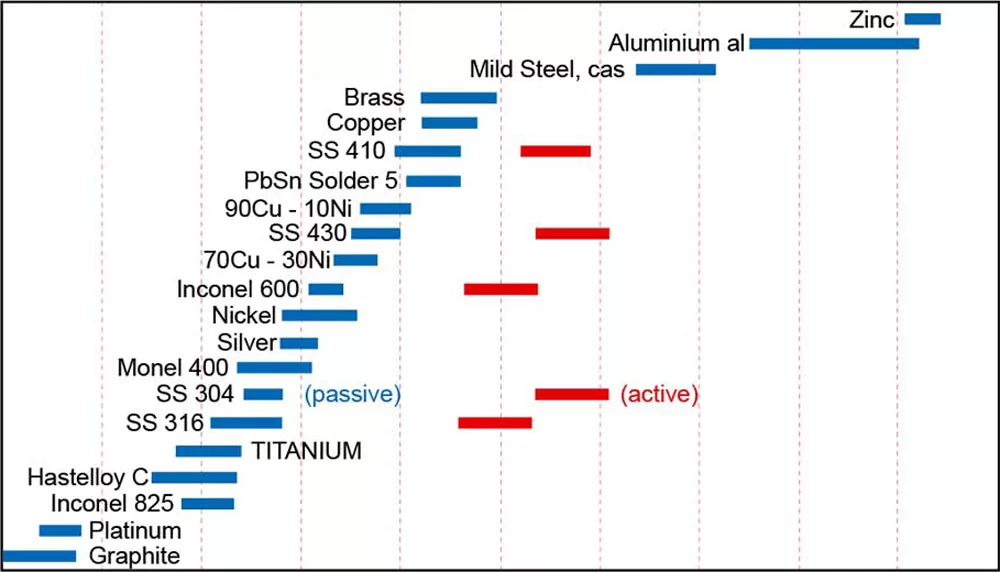

Galvic series in flowing sea water (2.5 – 4 m/sec, 10 – 27ºC)

Stress Corrosion Cracking

The commercially pure titanium alloys (grades 1, 2, 7, 11, 12) are immune to SCC except in a few environments, such as anhydrous methanol solutions containing halides, nitrogen tetroxide and red fuming nitric acid. The higher strength alloys have been found susceptible to SCC in aqueous chloride solutions at high stress levels in laboratory tests, but the problem is rarely encountered in practice.

Erosion Corrosion

The hardness of the surface oxide film gives excellent resistance to erosion corrosion, which is outstanding compared to most other candidates for heat exchanger service. High flow rates (30m/sec) can be used without problems due to inlet turbulence or pump cavitation effects.

Corrosion Fatigue

The highly protective surface oxide film results in insignificant reductions in fatigue strength in water, sea water and most chloride solutions where corrosion is not active.

Water & Sea Water

Titanium alloys corrode negligibly in sea water at temperatures up to 260ºC. Even under biofouling and deposits, pitting and crevice corrosion are not encountered. Marine atmospheres, splash and tidal zones, and soils also have no effect. Corrosion at tight design crevices may be seen in waters with higher than about 1000 ppm of chlorides at temperatures above about 75ºC.

Oxidising Media

Titanium alloys are highly resistant to oxidising acids, with corrosion rates typically less than 0.03 mm/year.

Corrosion of Titanium & Titanium Alloys

Introduction

Titanium and titanium alloys owe their excellent corrosion resistance to a stable, protective surface layer of titanium oxide. Titanium metal is highly reactive with oxygen, and the surface oxide forms spontaneously and instantaneously in contact with air and most media. Damage to the oxide film usually heals rapidly if the environment contains oxygen or moisture at the parts per million level. Hence titanium alloys are highly resistant to corrosion, usually corrode at negligible rates and require no corrosion allowance. However, anhydrous or highly reducing conditions may prevent the formation or healing of the oxide film, and corrosion may then become rapid.

This form of corrosion resistance is similar to that of aluminium and magnesium alloys, and of stainless steels, which also rely on a protective oxide film on the surface of a reactive metal.

PDF Downloads

Nickel Alloys & High Performance Alloys – Datasheet