Chemical Composition | Copper | Lead | Iron | Aluminium | Zinc | | Min | 55.0 | 1.5 | – | 0.10 | – | | Max | 60.0 | 3.0 | 0.30 | 0.60 | Remainder |

Equivalent Alloy Specifications| Specification | Designation | | UNS | C38010 | | ISO | CuZn43Pb3 | | BSI | CZ121 |

Australian Product Specifications| Specification | Product Form | | AS1567 | Wrought Rods, Bars & Sections | | AS2738 | Compositions & Designations |

Fabrication Properties| Joining Technique | Suitability | Soft Soldering | Good | Silver Soldering | Fair – Good | Brazing | Good | Oxy Acetylene Welding | Fair | Gas Shielded Arc Welding | Not Recommended | Coated Metal Arc Welding | Not Recommended | Resistance Welding | Not Recommended |

| | | Fabrication Technique | Suitability | Capacity for Being Cold Worked | Good | Capacity for Being Hot Worked | Good | Hot Working Temperature | 720 – 830 °C | Annealing Temperature | 450 – 550 °C | Stress Relieving Temperature | 250 – 350 °C | Machinability Rating | 80% of free cutting brass | Polishing/Electroplating Finish | Good |

|

Mechanical PropertiesTypical Room Temperature 20°C Temper | Tensile Strength Minimum | Elongation Minimum | Hardness Maximum | MPa | % | HV | | AS1567, Wrought Rods, Bars & Sections | 380 | 12 | 110 |

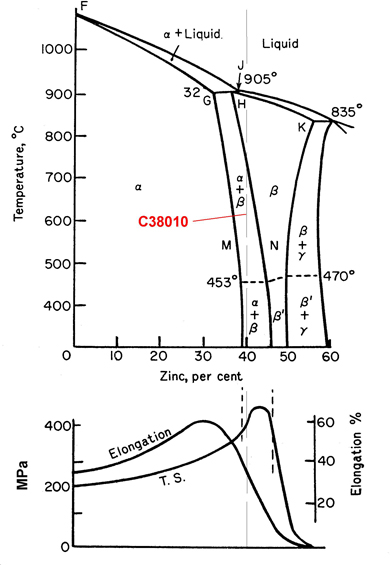

Available Forms Austral Wright Metals can supply Alloy C38010 as extruded sections – rods, angles, channels, flats & other extruded shapes. General Description Section brass is a readily extrudable leaded alpha / beta brass alloy with a small aluminium addition, which gives a bright golden colour. The alloy is supplied only as extruded sections and shapes, with a minimum amount of cold work. The bright gold colour is lost if severe cold working operations are applied – alloy 385 is a better choice for cold work. The lead addition renders the alloy free cutting, and it is used widely in components produced by automatic machining. C38010 weathers to a warm bronze tone. Typical applications. Include builders hardware. Physical Properties| Property | Metric Units | Imperial Units | Melting Point (Liquidus) | 890°C | 1635°F | Melting Point (Solidus) | 875°C | 1610°F | | | | Density | 8.47 gm/cm³ @ 20°C | 0.306 lb/in³ @ 68°F | Specific Gravity | 8.47 | 8.47 | | | | Coefficient of Thermal Expansion | 20.9 x 10 -6 / °C (20-300°C) | 11.0 x 10 -6 / °F (68-392°F) | Themal Conductivity | 121 W/m. °K @ 20°C | 70 BTU/ft³/ft/hr/°F @ 68°F | Thermal Capacity (Specific Heat) | 377 J/kg. °K @ 20°C | 0.09 BTU/lb/°F @ 68°F | | | | Electrical Conductivity | 0.162 microhm?¹.cm?¹ @ 20°C | 28% IACS | Electrical Resistivity | 6.16 microhm.cm @ 20°C | 38 ohms (circ mil/ft) @ 68°F | | | | Modulus of Elasticity (tension) | 96 GPa @ 20°C | 14.2 x 10 6 psi @ 68°F | Modulus of Rigidity (torsion) | 36 GPa @ 20°C | 5.3 x 10 6 psi @ 68°F | Poisson’s Ratio | 0.34 | 0.34 |

Phase Diagram & Mechanical Properties

Corrosion ResistanceC38010 has good corrosion resistance to weathering and fair resistance to many waters. C38010 should not be used in contact with ammonia, ammonia compounds or amines, as it may suffer stress corrosion cracking. Please consult Austral Wright Metals for advice on your specific application. |