Nickel Alloys Monel K-500 N05500

|

Product Data Sheet – Nickel Alloys |

Monel K-500 UNS-N05500 |

Monel K-500 is a nickel copper alloy combining the excellent corrosion resistance of Monel 400 with greater strength. It is widely used, particularly in marine and chemical processing applications. It has excellent resistance to sea water. Chemical CompositionASTM B865 – Bar, rod, wire, forgings & forging stock

Equivalent Specifications

ASTM Product Specifications

Specified Minimum Mechanical PropertiesASTM B865 – Bar, rod, wire, forgings & forging stock

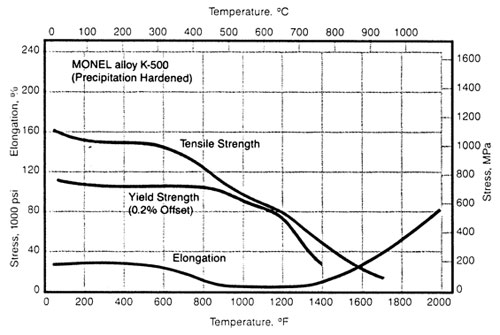

Available Forms Austral Wright Metals can supply Monel K-500 as plate, sheet and strip, rod and bar, tube and pipe, welding fittings, forgings and forging billet, wire. General Description Monel K-500 is a nickel copper alloy with high strength and good ductility, good weldability and excellent resistance to corrosion. It is tough over a wide range of temperatures. It is a precipitation hardening alloy, and a wide range of properties can be obtained by suitable heat treatments. It is often used in marine applications, particularly for pumps and propeller shafts. Corrosion resistance is substantially matches the excellent properties of Monel 400, except for greater susceptibility to stress corrosion cracking in some aggressive environments in the aged condition. Typical applications Pump shafts, propeller shafts, doctor blades and scrapers, springs, valve trim, fasteners. Physical Properties

Corrosion ResistanceMonel K-500 is generally more corrosion resistant that both of the major constituents nickel and copper. It is highly resistant to chlorinated solvents, glass etching agents, sulphuric, hydrofluoric and many other acids, and practically all alkalies. The alloy gives excellent service in sea water under high velocity conditions, where resistance to cavitation and erosion are important. Corrosion rates in strongly agitated and aerated sea water are extremely low. It is generally free from chloride stress corrosion cracking, but only annealed material resists stress cracking in the presence of mercury or mercury salts. Stress corrosion cracking in hydrofluoric acid vapours has also been encountered. Monel K-500 should not be used for nitric acid service. Please consult Austral Wright Metals for advice on your specific application.

Pressure VesselsMonel K-500 is not prequalified by AS1210 or the ASME Boiler & Pressure Vessel Code for use in pressure vessels. FabricationMonel K-500 can be readily hot worked, in the range 870°C to no higher than 1150°C. The forging should be water quenched from 790°C or higher. Care is needed in reheating practice. The alloy can be cold formed, with high forces even in the annealed condition, but ductility is good. MachinabilityMonel K-500 is best to machined when annealed, but can be finish machined when age hardened. During age hardening there is a slight, uniform contraction.

WeldabilityMonel K-500 is readily welded by GMAW (MIG), GTAW (TIG), SMAW (manual) and SAW processes. Preheat, post heat and post weld heat treatment are not required. The area around the weld must be clean to prevent contamination of the weld pool. Argon shielding gas is used. Welding should be done on annealed material, and the assembly stress relieved before ageing.

Heat TreatmentAdequate softening may be obtained by annealing at 760-870°C, but best response to subsequent ageing is achieved by annealing at 980°C for hot finished material and 1040°C for cold drawn products. Work should be water quenched after annealing. Addition of 2% alcohol to the quench water will minimise oxidation and facilitate pickling. The ageing treatment depends on the properties required, and Austral Wright Metals will be pleased to provide advice. Filler Metal Selection

|