Copper Alloys C26000 70-30 Brass

|

Product Data Sheet - Copper Alloys |

70-30 Brass UNS-C26000Also known as Cartridge Brass, Spinning Brass & Spring Brass |

Chemical CompositionAS1566 – 1997

Fabrication Properties

Mechanical PropertiesAS1566, Rolled Flat Products and AS1567 Wrought Rods, Bars & Sections

Available Forms Austral Wright Metals can supply this alloy as coil, sheet, plate, rods, bars, sections. See alloy C26130 (formerly alloy 259) for tube & fittings.

General Description 70/30 brass has excellent ductility and good strength. It is often used where its deep drawing qualities are needed. The alloy is the most common brass in sheet form.

Typical applications Architecture, grillwork, appliances, drawn & spun containers and components, radiator cores and tanks, electrical terminals, plugs and lamp fittings, locks, door handles, name plates, plumbers hardware, fasteners, cartridge cases, cylinder liners for pumps. Physical Properties

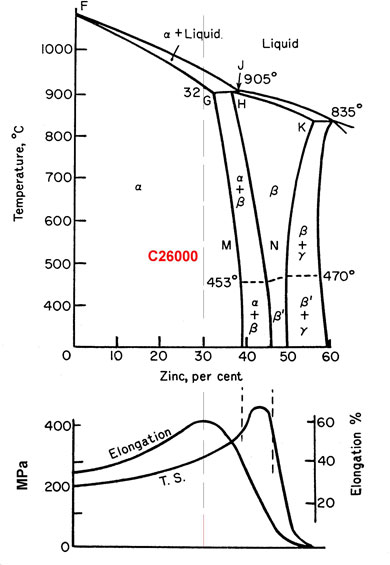

Phase Diagram & Mechanical Properties

Corrosion ResistanceC26000 has good corrosion resistance to weathering and very good resistance to many chemicals. It may undergo dezincification in stagnant or slowly moving salt solutions, brackish water or acidic solutions. Although it will resist most waters, C26130 is preferred as it contains a small arsenic addition which inhibits corrosion. |

The technical advice and recommendations made in this Product Data Sheet should not be relied or acted upon without conducting your own further investigations, including corrosion exposure tests where needed. Please consult current editions of standards for design properties. Austral Wright Metals assumes no liability in connection with the information in this Product Data Sheet. Austral Wright Metals supplies a comprehensive range of stainless steels, copper alloys, nickel alloys and other high performance metals for challenging service conditions. Our engineers and metallurgists will be pleased to provide further data and applications advice. |