Nickel Alloys Inconel Alloy 601 N06601

| |

Product Data Sheet – Nickel Alloys | |

Inconel® Alloy601™ UNS N0776601 | |

Inconel® Alloy 601™ is a solid solution nickel chromium heat resisting alloy which gives outstanding performance at temperatures up to about 1200°C. Inconel 601 also has good aqueous corrosion resistance due to the high nickel content in combination with chromium. Strength and toughness are good, and are retained during extended service at high temperature. Chemical CompositionASTM B166 – Rod, Bar & Wire

Specified Minimum Mechanical PropertiesASTM B166 – Bar (Annealed)

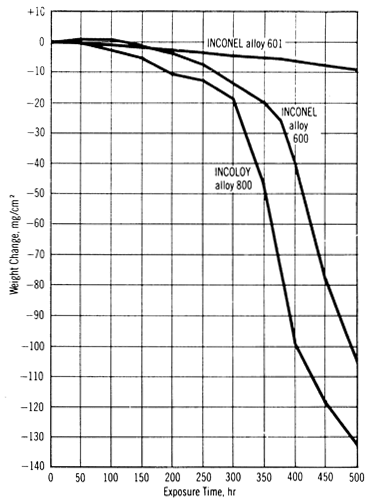

Typical ApplicationsThermal processing equipment – baskets, trays, fixtures, radiant tubes, muffles, retorts, flame shields, woven wire conveyers, burner nozzles and electrical resistance heating wires. Other applications include thermocouple protection tubes, process heaters, condenser tubes, catalyst supports in nitric acid manufacture, exhaust systems in gasoline engines and combustion chambers, superheater tube supports and ash handling in power generation. DescriptionInconel 601 is a solid solution nickel chromium alloy for high temperature heat resistance. It has excellent oxidation resistance. Inconel 601 also has good resistance to carburising but should not be used in atmospheres containing sulphur, particularly reducing sulphur. Inconel 601 has good resistance to nitriding in dissociated ammonia, and is only outperformed by Inconel 600 in this application. Inconel 601 has good strength, ductility and toughness, and can be used at cryogenic temperatures. AvailabilityAustral Wright Metals can supply Inconel 601 as plate, sheet and strip, rod and bar, seamless tube and pipe, wire, forgings and forging stock. Oxidation ResistanceInconel 601 has outstanding resistance to high temperature oxidation. It resists oxidation and spalling at temperatures as high as 1260°C. The protective oxide coating resists scaling even under severe conditions, and the alloy also has good resistance to carburisation and nitridation. Its resistance to sulphur is poor and it should not be used in atmospheres containing sulphur, particularly reducing sulphur.

Each cycle was 50 hours at temperature, then air cooled to room temperature. |

Pressure Vessels

Inconel 601 is qualified for use in pressure vessels in ASME Section VIII (Code case 1500) to 480°C. It is not pre qualified in AS1210.

Corrosion Resistance

Inconel 601 has excellent corrosion resistance to the mineral acids, similar to Inconel 600. Inconel 601 has good resistance to sodium hydroxide solutions and because of the high nickel content good resistance to chloride stress corrosion cracking. As with austenitic stainless steels Inconel 601 can be sensitised to intergranular corrosion in some aggressive media after heating in the temperature range 540 – 760°C. Please consult Austral Wright Metals for your specific application.

Fabrication

Inconel 601 is readily hot worked. Inconel 601 must be clean before heating is commenced and should not be heated in an atmosphere high in sulphur. This alloy can be cold formed similarly to austenitic stainless steel. Work hardening in cold forming may require intermediate annealing.

Machinability

Inconel 601 as a ‘C’ class alloy is fairly difficult to machine. Heavy machines, sharp tools, slow speeds and deep cuts to remove the work hardened layer are needed.

Weldability

Inconel 601 is readily weldable by the SMAW (manual), GMAW (MIG), GTAW (TIG) and SAW processes. Preheat or post weld heat treatment are not needed. Care must be taken to avoid contamination of the weld pool. Argon is used as the shielding gas.

Filler Metal Selection

| Normal Service | Higher Strength | Best Corrosion Resistance | |

| Welding Electrode | Inconel WE 182 | Inconel WE 117 | N/A |

| Filler Metal | Inconel FM 82 | Inconel FM 617 | Inconel FM 601 |

| Flux Cored Wire | Inco Cored 82DH | N/A | N/A |

Heat Treatment

Inconel 601 is solution annealed at 1100 – 1180°C, and cooled quickly so as to avoid sensitisation to intergranular corrosion. Annealing time should be short to avoid excessive grain growth.

Equivalent Specifications

| Country | Body | Grade |

| USA | UNS | N06601 |

| France | AFNOR | NC 23 FeA |

| GB | BS | – |

| Germany | DIN | 2.4851 |

Physical Properties

| Property | Metric Units |

Density | 8,110 kg/m³ @ 20°C |

Melting Point | 1360-1411°C |

Electrical Resistivity | 1190 micro-ohm . m @ 20°C |

Specific Heat | 448 J/kg . °C @ 20°C |

Mean Coefficient of Expansion | 13.8 x 10-6 / °C @ 20°C |

Thermal Conductivity | 11.2 W / m . °C @ 20°C |

Curie Temperature | -320°C |

Modulus of Elasticity | |

Tension | 207 GPa @ 20°C |

Torsion | 81.2 GPa @ 20°C |

Poisson’s Ratio | 0.272 @ 20°C |

ASTM Product Specifications

| Specification | Title |

| B166 | Nickel Chromium Iron and Nickel Chromium Molybdenum Rod, Bar and Wire |

| B167 | Nickel Chromium Iron Seamless Pipe |

| B168 | Nickel Chromium Iron Alloys and Nickel Chromium Cobalt Molybdenum Alloy Plate, Sheet and Strip |