Nickel Alloys Inconel Alloy 600 N06600

| |

Product Data Sheet – Nickel Alloys | |

Inconel® Alloy600™ UNS N06600 | |

Inconel® Alloy 600™ is a solid solution nickel chromium alloy for high temperature applications. Inconel 600 has good mechanical strength and can be used from cryogenic temperatures to 1200°C. It also has good corrosion resistance due to the high nickel content in combination with chromium. Chemical CompositionASTM B166 – Rod (Annealed)

Specified Minimum Mechanical PropertiesASTM B166 – Bar (Annealed)

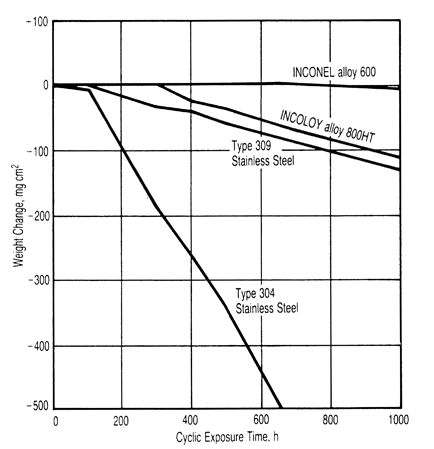

Typical ApplicationsHeat treating muffles and retorts, heat treating baskets, chlorination equipment to 540°C, pulp mill alkaline digesters. Other applications include heaters, stills, bubble towers, condensers for processing fatty acids, evaporator tubes, tube sheets and flaking trays for sodium sulphite manufacture, springs primary water pumping. AvailabilityAustral Wright Metals can supply Inconel 600 as plate, sheet and strip, rod and bar, seamless and welded tube and pipe, welding fittings, forgings, forging billet, wire. High Temperature ApplicationsInconel 600 has excellent resistance to oxidation at high temperatures. It is the standard material for nitriding containers because of its resistance to nitrogen at high temperatures. It also has good resistance to carburisation. Inconel 600 will resist attack by sulphur compounds at moderate temperatures, but is subject to sulphidation at higher temperatures. Lubricants containing molybdenum disulphide should not be used above 425°C. Inconel 600 is not embrittled by long exposures at high temperature. Pressure VesselsInconel 600 is approved under AS1210 and ASME boiler and pressure vessel code Sections I (Code case 1827), III, VIII for temperatures up to 650°C.

Corrosion ResistanceInconel 600 has good corrosion resistance to many media. In feed water systems it is practically free of corrosion. It resists flowing sea water, but will corrode in stagnant sea water. The alloy has fair resistance to sulphuric acid at room temperature, but should not be used in this application at elevated temperatures. Resistance to hydrochloric acid is similar to sulphuric acid. The alloy has excellent resistance to phosphoric acid at room temperature in all concentrations, but is rapidly attacked at elevated temperature. Inconel 600 is practically free from chloride ion stress corrosion cracking. Please consult Austral Wright Metals for advice on your specific application. Oxidation ResistanceInconel 600 has good resistance to oxidation at high temperature. It out performs all other alloys for resistance to nitridation in cracked ammonia. It should not be used in sulphur containing atmospheres at high temperature, particularly if the conditions are reducing. It resists dry chlorine and hydrochloric acid gas at moderate temperatures. FabricationInconel 600 can be hot forged. The surface should be clean before heating. Solution annealing after forging is normal. Inconel 600 is readily cold formed by standard processes and equipment. Work hardening in cold forming may require intermediate anneal. MachinabilityInconel 600 is reasonably easy to machine (class “C” alloy). Heavy machines, sharp tools, slow speeds and deep cuts to remove the work hardened layer are needed. WeldabilityInconel 600 is readily welded by the SMAW (manual), GMAW (MIG), GTAW (TIG) and SAW processes. Preheat, post heat and post weld heat treatment are not needed. Contamination of the weld pool should be avoided. Inconel welding electrode 182 or Inconel filler metal 82 are normally used as welding consumables. Argon is used as the shielding gas. Filler Metal Selection

Heat TreatmentAnnealing at 1010°C for 15 minutes softens Inconel 600. Solution heat treatment is done at 1090 – 1150°C to dissolve carbides. Care should be taken with heat treatment as it affects corrosion resistance and high temperature properties. Equivalent Specifications

Physical Properties

ASTM Product Specifications

|