Stainless Steels Nitronic 50 S20910

|

Product Data Sheets Stainless Steels |

Nitronic 50, 50HS UNS S20910 |

NITRONIC 50 is a high strength austenitic stainless steel with excellent corrosion resistance, used where grades 316 and 316L are only marginal. NITRONIC 50HS is a higher strength version, available only in heavy section bar. Chemical Composition

Typical ApplicationsPumps, valves and fittings, fasteners, cables, chains, screens & wire cloth, marine hardware, boat shafting, non magnetic fasteners & chains, heat exchanger parts, in the petroleum, petrochemical, chemical, pulp and paper, textile, food processing & marine industries. Specified Minium Mechanical PropertiesAnnealed and High Strength Bar

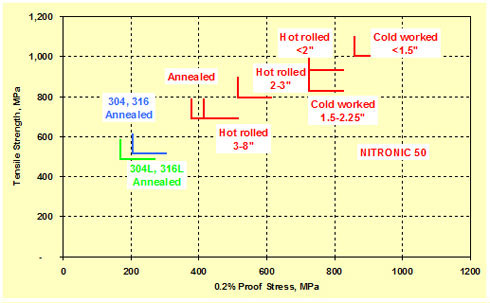

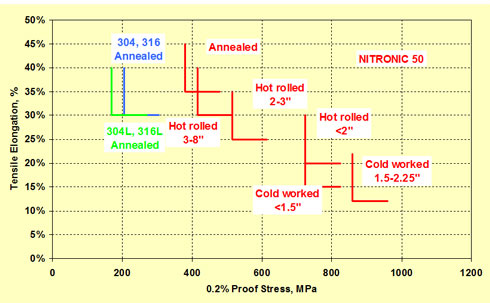

DescriptionNITRONIC 50 is an austenitic stainless steel with an outstanding combination of strength, toughness and corrosion resistance. It can be supplied in the annealed condition, with yield strength over 50% higher than grades 316 and 316L, with better corrosion resistance. It is also available as NITRONIC 50HS with high strength, attained by special processing techniques. The superior strength of NITRONIC 50HS is size dependent, approaching that of annealed bars at diameters of over 75 mm, but at sizes up to 32 mm a yield strength of 895 MPa can be obtained – about four times the strength of grade 316. AvailabilityAustral Wright Metals can supply Nitronic 50 as bar, wire, forgings, forging billets and precision balanced shafts. Nitronic 50HS is available as bar and precision balanced shafts. Comparison of Tensile PropertiesBars of NITRONIC 50, 50HS and grades 304(L), 316(L) (ASTM A479)

Corrosion ResistanceThe high chromium and molybdenum contents of NITRONIC 50 & 50HS give outstanding corrosion resistance, superior to grades 316 and 316L in many media, and rivalling nickel alloys in seawater. For most applications, the 1065°C annealed condition provides adequate corrosion resistance and a higher strength level. In very corrosive media, or where the material is to be used in the as welded condition, the 1120°C condition should be specified. NITRONIC 50HS bars are useful for applications such as shafts & bolts, but do not quite have the corrosion resistance of the annealed condition in all environments. After exposure to 5% NaCl fog at 35°C for 500 hours, and after exposure to marine atmospheres 24 m from the high water line at Kure Beach, USA, for 7½ years, no change was visible in NITRONIC 50. Similar exposure to marine atmospheres produces light staining on grade 316 stainless steel. NITRONIC 50 has given satisfactory service in challenging corrosion conditions such as pump parts for sodium carbamate (an intermediate in the production of urea), in sour gas service for oilfield equipment, in food handling equipment and in boat shafting used in seawater. As with other austenitic stainless steels, NITRONIC 50 may undergo stress corrosion cracking in hot chloride environments. Testing in boiling 42% magnesium chloride solution, a very accelerated test, shows NITRONIC 50 is between grades 304 and 316 in cracking resistance. There is little difference in susceptibility whether in the annealed, high strength or cold drawn conditions. FabricationThe fabricating equipment and techniques used for austenitic stainless steels can be used. In-process annealing should be done at 1120°C. Cooling practices are the same as those required for grade 304. Forging temperatures of 1175°C to 1230°C are recommended. MachinabilitySlower speeds and higher feeds are required compared to austenitic stainless steels. NITRONIC 50 can be machined at approximately half the cutting rate used for grades 304 and 316. Heavy machines and tools are needed. Tools should not be allowed to slide over the alloy, & cutting action should be initiated as soon as possible. The alloy gives good surface finish. WeldabilityNITRONIC 50 has good welding characteristics, similar to austenitic stainless steels. Any of the usual arc welding processes can be used. Preheat or post weld annealing are not generally needed. To avoid weld metal hot cracking, choose weld filler metal to give a ferrite number of about 6. Retaining the low magnetic permeability of parent metal requires post weld heat treatment to remove the ferrite. NITRONIC 50W welding consumables are available to give welds of comparable strength and corrosion resistance to the base metal. Sound weld joints of lower strength and corrosion resistance may be made using conventional austenitic filler metals such as grades 308(L) and 309(L).

Physical Properties

NITRONIC 50 is covered by the following specificationsas grade XM-19 (UNS S20910)

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||